Aluminium Sheet Manufacturers in Qatar

Introduction

The world of industrial manufacturing relies heavily on materials that can withstand the demands of modern applications. Aluminum, in particular, has emerged as a cornerstone in industries such as aerospace, military tanks, automotive, shipbuilding, and marine hardware. Its unique combination of lightweight strength, versatility, and corrosion resistance makes it indispensable in these fields. For industries in Qatar, finding a reliable supplier of high-quality aluminum sheets is paramount. Yatha Overseas, established in 1999, has consistently delivered top-notch aluminum materials that meet the rigorous demands of these industries. With over two decades of experience, Yatha Overseas is recognized as a leading name in aluminum sheet manufacturing and supply, ensuring that clients receive products of the highest standard.

Why Choose Aluminum?

- Lightweight Strength: Aluminum’s low density contributes to a high strength-to-weight ratio, a crucial factor in sectors like aerospace and automotive. Aircraft components made from aluminum are both durable and lightweight, improving fuel efficiency and reducing operational costs.

- Versatility: Aluminum can be easily shaped, welded, and machined to meet diverse industrial requirements. From intricate aerospace components to robust automotive parts, aluminum’s adaptability makes it a versatile choice.

- Eco-Friendly: With growing awareness about environmental sustainability, aluminum stands out as a recyclable material that retains its properties throughout recycling processes.

Yatha Overseas: A Trusted Name Since 1999

Since its inception in 1999, Yatha Overseas has been synonymous with quality and reliability in the metal manufacturing industry. The company’s foundation is built on the principles of excellence, innovation, and customer satisfaction. Yatha Overseas specializes in the manufacturing, stocking, and supply of high-grade aluminum sheets and plates. Their commitment to delivering superior products has earned them recognition not only in Qatar but across international markets. Over the years, they have continually adapted to advancements in technology and changes in market demands, solidifying their position as a trusted provider for clients in diverse industries.

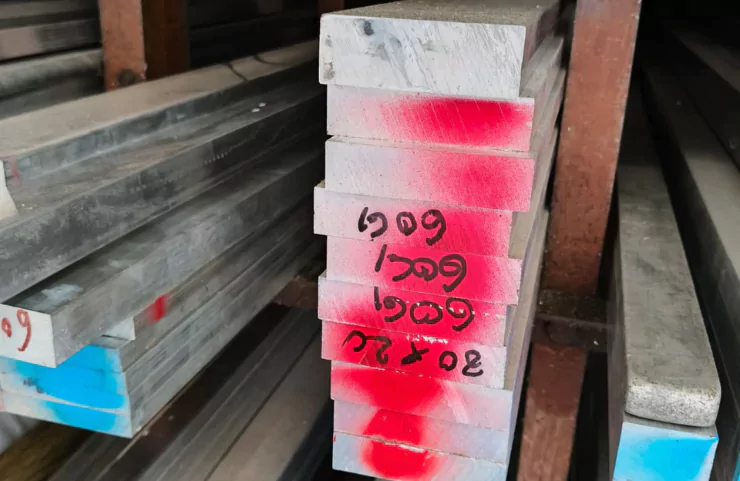

Comprehensive Alloy Portfolio

- 1050 and 1100: These alloys are widely recognized for their superior corrosion resistance and high thermal conductivity. Applications include heat exchangers and chemical storage tanks.

- 6063 and 6068: Known for their excellent strength and aesthetic appeal, these alloys are used in architectural structures, window frames, and curtain walls.

- 7075: One of the strongest aluminum alloys, 7075 is predominantly used in aerospace applications. Its high strength and durability make it a reliable choice for aircraft components and other demanding uses.

- 2014: With high strength and excellent machinability, this alloy is preferred in military applications, including armored vehicles and tanks.

Industries Served

- Aerospace: Aluminum’s lightweight properties are crucial for aircraft manufacturing, where reducing weight directly impacts fuel efficiency and operational costs.

- Military Tanks: In the defense sector, aluminum is vital for constructing military tanks that require durability without compromising mobility.

- Automotive: As the automotive industry shifts towards sustainability, aluminum’s role has become increasingly important.

- Shipbuilding and Marine Hardware: Saltwater environments pose significant challenges to materials used in marine applications.

Focus on Quality and Certification

Quality is the cornerstone of Yatha Overseas’ operations. The company adheres to rigorous quality control measures to ensure that every product meets international standards. Their manufacturing processes are designed to maintain precision, consistency, and reliability across all product lines. Yatha Overseas has achieved certifications that testify to their commitment to excellence. These certifications instill confidence in clients, assuring them that the products they receive are of superior quality and engineered to meet industry demands.

Innovative Manufacturing Process

At the heart of Yatha Overseas’ success is their dedication to innovation. The company employs advanced manufacturing techniques and state-of-the-art technology to produce aluminum sheets of unmatched quality. From initial design to final production, every step is meticulously managed to ensure precision and efficiency. Their focus on innovation extends to sustainability, with eco-friendly practices integrated into their manufacturing processes. By reducing waste and optimizing resource usage, Yatha Overseas aligns itself with global efforts to promote environmental responsibility.

Environmental Impact of Aluminum Production and Recycling

The environmental benefits of aluminum extend far beyond its applications; its production and recycling processes contribute significantly to sustainability efforts worldwide. Aluminum is one of the few materials that retains its inherent properties even after being recycled multiple times. This makes it an eco-friendly option for industries aiming to reduce their environmental footprint. The recycling process requires only about 5% of the energy needed for primary aluminum production, substantially lowering greenhouse gas emissions and conserving natural resources. For example, automotive and aerospace sectors, which generate considerable aluminum waste, can benefit from closed-loop recycling systems.

Innovation in Aerospace Materials

The aerospace industry is synonymous with cutting-edge innovation, and aluminum remains a pivotal material in this realm. Modern aerospace designs demand materials that are lightweight, durable, and capable of enduring extreme conditions. Aluminum meets all these criteria, making it indispensable for aircraft, drones, and spacecraft. Alloys such as 7075 and 2024, supplied by Yatha Overseas, are specifically engineered for aerospace applications. These alloys offer exceptional strength and fatigue resistance, enabling the construction of fuselage sections, wing panels, and landing gear.

Challenges in Marine Applications and Aluminum’s Solutions

Marine environments present unique challenges for materials due to constant exposure to saltwater, humidity, and fluctuating temperatures. Traditional materials often succumb to corrosion and wear, leading to frequent replacements and high maintenance costs. Aluminum, however, offers a reliable solution to these challenges. Alloys like 5052 and 5083, provided by Yatha Overseas, are specifically tailored for marine applications. These alloys are known for their superior corrosion resistance, ensuring the longevity of vessels and marine equipment. Whether it’s for ship hulls, boat fittings, or offshore platforms, aluminum’s durability significantly reduces maintenance requirements.

Benefits of Partnering with Yatha Overseas

Choosing the right supplier can make all the difference in the success of a project, and Yatha Overseas stands out as an industry leader for several reasons. Their customer-centric approach ensures that every client receives personalized service, from product selection to delivery. By understanding the specific needs of each industry, they offer tailored solutions that go beyond merely supplying materials. Yatha Overseas excels in maintaining transparency, reliability, and consistency in their operations. Their expertise in handling complex logistics ensures timely delivery, even for large-scale international projects. Additionally, their technical team provides support and guidance, helping clients select the most suitable alloys for their applications.

Future Prospects in Aluminum Manufacturing

As industries transition towards advanced technologies and sustainable practices, aluminum is poised to play an even greater role in shaping the future. Innovations such as electric vehicles, renewable energy systems, and smart construction projects demand materials that combine strength, versatility, and eco-friendliness. Aluminum meets these requirements, ensuring its continued relevance across sectors. Yatha Overseas is prepared to meet these evolving demands by continuously expanding their alloy portfolio and investing in advanced manufacturing technologies. Their vision for the future aligns with industry trends, ensuring they remain a trusted partner for clients seeking innovative solutions.

Advanced Applications of Aluminum in Modern Technology

- Robotics: Aluminum alloys are widely used in the development of robotic arms and structural frames due to their strength and machinability. These features ensure precision and reliability, which are essential in robotics.

- Electronics: In consumer electronics, aluminum is increasingly employed in device housings and internal components. Its ability to dissipate heat efficiently makes it ideal for products such as laptops, smartphones, and servers, ensuring optimal performance.

- Renewable Energy: Aluminum contributes significantly to the growth of sustainable energy. From solar panel frames to wind turbines, its corrosion resistance and adaptability make it a preferred material for energy generation systems.

Customization and Tailored Solutions by Yatha Overseas

- Industry-Specific Solutions: Whether for aerospace components, automotive panels, or marine structures, Yatha Overseas provides aluminum sheets and plates in custom sizes and specifications. This ensures optimal performance for specialized applications.

- Technical Expertise: The company’s team of experts collaborates closely with clients to understand project requirements and recommend the most suitable alloys. Their guidance ensures that the chosen materials meet both technical and operational demands.

FAQs About Aluminium Sheet Manufacturers

Q.1: What types of aluminum alloys are available at Yatha Overseas?

Ans. Yatha Overseas offers a wide range of high-quality aluminum alloys, including 1050, 1100, 6063, 6068, 7075, 5052, 2014, 5083, and 2024.

Q.2: What industries does Yatha Overseas serve?

Ans. Yatha Overseas serves a diverse array of industries, including aerospace, military, automotive, shipbuilding, and marine hardware.

Q.3: How can I contact Yatha Overseas for inquiries or orders?

Ans. To learn more about their products or place an order, you can contact Yatha Overseas through their website yathaoverseas.com or call them directly at +919820525505.

Conclusion

In an era where quality and precision drive industrial progress, Yatha Overseas stands out as a reliable partner for aluminum sheet manufacturing and supply. With over two decades of experience, a diverse alloy portfolio, and a commitment to sustainability, Yatha Overseas caters to the demanding needs of industries like aerospace, military, automotive, shipbuilding, and marine hardware. Their emphasis on innovation, quality, and customer satisfaction has solidified their position as a leading name in aluminum manufacturing, not only in Qatar but across global markets. Whether you need lightweight materials for advanced aerospace applications or corrosion-resistant sheets for marine environments, Yatha Overseas provides tailored solutions that ensure your project’s success.

“Don’t forget to share this post!”