Aluminium Sheet Metal Manufacturers in Al Khor, Qatar: Spotlight on Yatha Overseas

Aluminium Sheet Metal Manufacturers in Al Khor, Qatar: Spotlight on Yatha Overseas

Whether you’re sourcing industrial-grade aluminium sheet metal or innovative architectural solutions, choosing a trusted manufacturer in Al Khor, Qatar can make all the difference. In this comprehensive guide, we shine the spotlight on Yatha Overseas, showcasing their expertise, manufacturing process, product offerings, and why they stand out in the regional market.

Introduction to Aluminium Sheet Metal in Al Khor

Aluminium sheet metal permeates numerous industries—from construction and automotive to signage and HVAC systems. And in Qatar’s dynamic industrial environment, Al Khor plays a pivotal role as a rising manufacturing hub. But amid several players, finding a reputable aluminium sheet metal manufacturer can be challenging. Thankfully, Yatha Overseas has built a reputation for delivering premium-grade sheets, precision fabrication, and timely delivery, especially in the Al Khor region. In this post, we’ll uncover why they’re a top choice, how they meet customer needs, and why their quality benchmarks matter.

Why Choose Local Manufacturers in Al Khor?

First, let’s explore why proximity matters in sheet metal sourcing. When you opt for a manufacturer based in Al Khor, you gain:

- Faster Turnaround Times – No need for international shipping; Yatha Overseas streamlines your project timelines.

- Lower Logistics Costs – Reduced freight, duty, and handling.

- Enhanced Communication – Face-to-face collaboration leads to better customization.

- Regulatory Familiarity – Quick compliance checks with Qatar’s industrial regulations.

- Local Responsibility – Support local industry and contribute to regional economic development.

Moreover, Al Khor’s expanding industrial infrastructure—including Qatar’s major ports and free zones—makes it an ideal place for quality-focused manufacturing.

Meet Yatha Overseas: A Trusted Name in Aluminium Manufacturing

With over a decade of hands-on experience, Yatha Overseas has strategically positioned itself as a specialized aluminium sheet metal manufacturer serving clients across Qatar and the GCC. So, who exactly are they?

Company Snapshot

- Established: Mid-2010s, with robust growth each year

- Location: Manufacturing facility near Al Khor Industrial Area

- Mission: To provide top-tier aluminium sheet metal solutions, combining precision engineering with fast delivery

Why Yatha Stands Out

- Technical Expertise

Their engineering team confidently handles tasks ranging from basic shearing and bending to complex CNC profiling and perforation. - Bespoke Solutions

They produce custom panels, chassis, brackets—with tolerances often achieved within ±0.1 mm. - Responsive Customer Service

Their project coordinators manage everything from design consultations to on-site installation. - Comprehensive Support

From material selection advice (3003, 5052, 6061 alloys) to post-sales care—Yatha ensures seamless execution.

Later sections will detail their capabilities, but suffice it to say: Yatha Overseas balances industrial capacity with attentive solutions tailor-made for each client.

Manufacturing Capabilities & Processes

At Yatha Overseas, the journey from raw aluminium coil to finished sheet metal product is handled with precision. Let’s walk through the key stages:

1.Raw Material Sourcing

- Alloy Varieties:

Certified stocks like 1100, 3003 (cost-effective), 5052 (marine-grade), 6061-T6 (structural strength) - Supplier Qualifications:

Suppliers vetted to meet EN 485 and ASTM B209 standards - Traceability:

Every batch is tracked via mill certificates ensuring quality and origin transparency

2.Shearing & Cutting

- Guillotine Shears:

For clean, burr-free cuts up to 3 mm thickness - CNC Laser & Plasma Cutting:

Enables complex shapes, slots, and cut-outs with micron-level accuracy

3.Forming & Bending

- Press Brakes:

Hydraulic and CNC press brakes capable of bending aluminium up to 6 mm thick - Roll Formers:

For producing continuous profiles like flashings, louvers, channels

4.CNC Machining & Profiling

- Router Tables:

3-axis CNC routers for cabinet panels, facades, and control-box enclosures - Perforation Machines:

Custom hole patterns, from architectural screening to ventilation panels

5.Surface Finishing

- Anodizing:

Available in natural, bronze, black, custom colors, with corrosion resistance - Powder Coating:

In RAL palette with thickness always verified via dry-film gauges - Polishing & Brushing:

For cosmetic finishes on decorative or architectural elements - Custom Lamination:

Woodgrain, stone finishes, and anti-graffiti overlays

Product Range & Custom Solutions

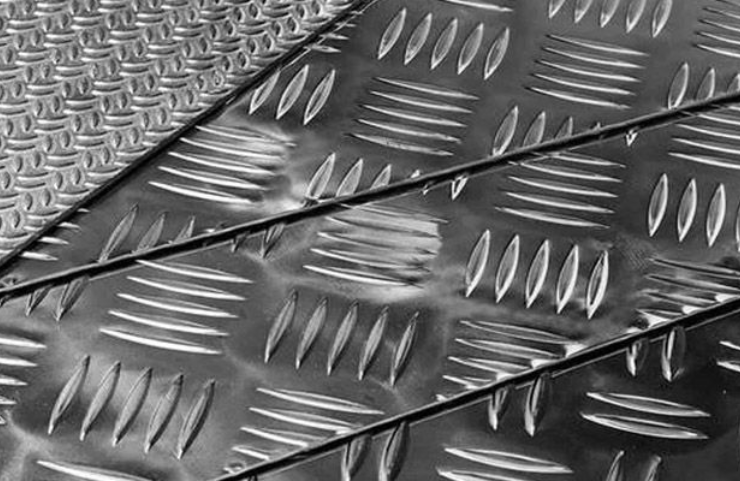

1.Standard Aluminum Sheet Panels

According to regional construction data:

- Aluminium consumption in Qatar is projected to grow 15% annually

- Al Khor’s offshore projects increasingly require marine-grade aluminium

- Green building initiatives are pushing demand for recyclable materials like aluminium

2.Slotted & Perforated Panels

- Perforation Patterns: Round, square, slot, hexagonal, bespoke

- Open Area Range: 10%–60%

- Applications: Sunshades, machine guards, decorative facades

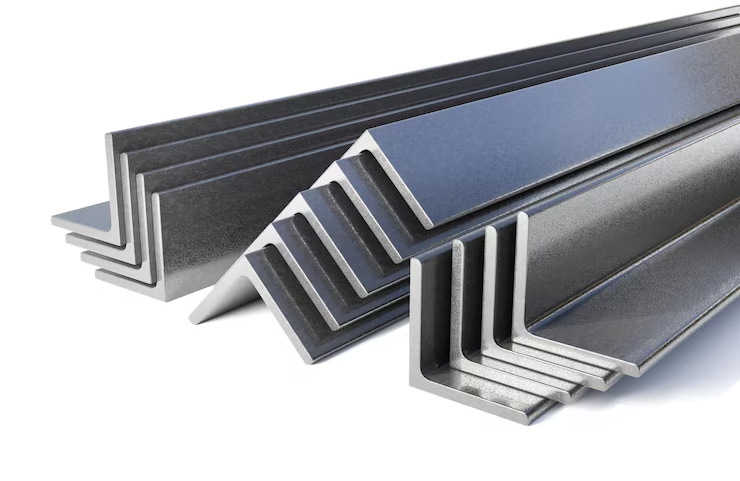

3.Custom Fabricated Items

- Brackets and Angles: For mounting, cladding, solar arrays

- Channeling & Flashing Profiles: Roof lining and window trims

- Enclosures: Push-out or hinged panels for electrical cabinets

4.Architectural Cladding and Façade Boards

- Composite Panels: Aluminium face bonded to fire-retardant cores

- Cassette Panels: Concealed fix for easy installation and replacement

- Perforated Screens: For solar shading and aesthetic façade solutions

5.Finished Components

- Coated Heat Sinks: For electronics, with anodized surfaces for thermal performance

- Decorative Inserts: Brushed/polished trim for elevators, lifts, interiors

Crucially, Yatha can match AAMA, ASTM, EN standards for architectural applications—a decisive factor for discerning customers.

Advanced Technologies & Innovation

To stay competitive, Yatha embraces innovation across several fronts:

- Digital Twin Modeling: Simulate fabrication workflows to reduce errors and lead times

- AI-powered Cut Optimization: Maximize material use and reduce scrap

- Robotic Finishing Cells: For consistent powder coating on large panels

- Smart Factory Initiatives: IoT-monitored production lines that alert on machine downtime

- Sustainable Production Models: Waste aluminium is recycled; chemical baths are reused after treatment

Hence, Yatha’s investment in industrial automation ensures faster delivery, better quality, and reduced waste.

Sustainability & Environmental Commitment

Sustainability isn’t just trendy—it’s imperative. Yatha Overseas champions eco-conscious practices:

- Magnesium Hydroxide Anodizing: Eliminates chromates and reduces water use

- VOC-Free Powder Coating: Lowers emissions in line with European environmental targets

- Closed-Loop Water Systems: Treat rinse and wash water for reuse

- Aluminium Recycling Program: Collects and reprocesses fabrication scrap

- Renewable Energy Usage: Solar panels supplement power for extruders and coaters

Consequently, clients looking for green aluminium solutions find Yatha’s practices compelling—not only for compliance, but for reduced carbon footprint.

Applications Across Industries in Qatar

- Construction & Architecture

From curtain walls to sun-shade fins and decorative cladding, Yatha enables sleek exteriors that withstand Qatar’s harsh climate. - Transportation

Custom housings, brackets, and panels for mass transit, vehicles, and airport infrastructure. - Electrical & Electronics

Panels, photon sinks, cabinet enclosures—designed for thermal conductivity and structural strength. - HVAC & Mechanical Systems

Lightweight ducting, louvers, and access panels that are corrosion-resistant and easy to install. - Signage & Displays

Backings for channel letters, billboard panels, and wayfinding signage—designed for weather resistance and printability. - Marine & Offshore

Marine-grade 5052 panels for boat interiors, offshore platforms, and boundary fencing.

Such cross-sector utility reinforces why Yatha is a go-to aluminium sheet metal supplier in Al Khor.

Export & Logistics Excellence

Although based in Al Khor, Yatha also ships across the GCC and globally—here’s how

- Strategic Location: Proximity to Hamad Port and Hamad International Airport enables prompt dispatch

- Packaging: Export-grade wooden crates with anti-rust protection, shock-absorbing foam

- Customs Expertise: Handles Qatari regulatory compliance, certifications of origin, and HS codes

- Global Partners: TIE with freight forwarders, ensuring cost-effective ocean and air cargo

- Tracking & Documentation: Provides full Bill of Lading, packing list, MTC, CoC with ISO labels

This export readiness makes Yatha a viable GCC aluminium sheet metal exporter.

Pricing, Cost Efficiency & Value Proposition

Many assume that bespoke aluminium means costly. However, Yatha leverages robust processes and local production to deliver competitive pricing.

Why Yatha Offers Great Value:

- Local Sourcing: Avoids import duties and transit delays

- Economies of Scale: Bulk alloy orders and standardized processes reduce costs

- Low Scrap Rates: AI-driven cutting minimizes material waste

- Modular Production: Reduces cost of customization

Pricing Model Highlights

- Pricing based on alloy, thickness, panel size, finish, and volume

- Free initial quote with CAD review + lead time estimate

- For large/recurring orders, contract adjustments and payment terms are negotiable

Together, these advantages mean clients enjoy high-quality aluminium sheet metal at cost-effective rates with predictable budgets.

Industry Trends & Future Outlook

As Qatar continues its infrastructure expansion, aluminium manufacturing evolves:

- Hybrid Materials: Composite panels with thermal insulation

- Smart Panels: Embedded sensors for structural health monitoring

- Lightweight Mobility: EVs and transport systems requiring lightweight alloy components

- 3D-Printed Patterns: Rapid prototyping before actual fabrication

- Circular Economy Models: Closed-loop scrap collection in GCC

Given these developments, Yatha is investing in R&D, stronger local supply chains, and smarter finishing facilities—positioning them well for evolving market needs.

Frequently Asked Questions (FAQs):Aluminium Sheet Metal Manufacturing

Q1: What alloys do you manufacture?

A1: We work with 1100, 3003, 5052, 6061, 6063 alloys, tailored to structural, aesthetic, or marine requirements.

Q2: Can I get custom-sized panels?

A2: Absolutely. We offer custom cuts, perforations and finished sizes with ±0.05 mm tolerance.

Q3: What finishes are available?

A3: Anodizing, powder coating (120+ RAL colors), brushing, polishing, and laminated surfaces.

Q4: What’s the typical lead time?

A4: Normally 2–4 weeks depending on quantity, complexity, and finish. Express options available.

Q5: Do you handle installation?

A5: Yes, for architectural projects in Qatar—especially around Al Khor. We coordinate with onsite teams for smooth delivery.

Conclusion: Your Aluminium Partner in Progress – Yatha Overseas

To sum up, Yatha Overseas exemplifies what it means to be high-quality aluminium sheet metal manufacturers in Al Khor, Qatar—combining local responsiveness with international standards. Their expansive product portfolio, advanced fabrication techniques, sustainable practices, and dedicated customer support make them a compelling partner for architects, contractors, and industrial buyers. If you’re planning a project requiring custom-cut panels, coated façades, or precision-machined aluminium components, reach out to Yatha Overseas today. Let their engineering prowess and regional proximity help streamline your next build.

“Don’t forget to share this post!”